The new pewter alloys differed from the older high lead

content miniatures in two important ways.

The metal was harder and therefore more difficult to clean up any

casting flaws and mold lines. The metal

was also more expensive than the older alloys leading to across the board price

increases for miniatures. Largely

because of the later issue, manufacturers began to experiment more with alternate

materials for miniatures.

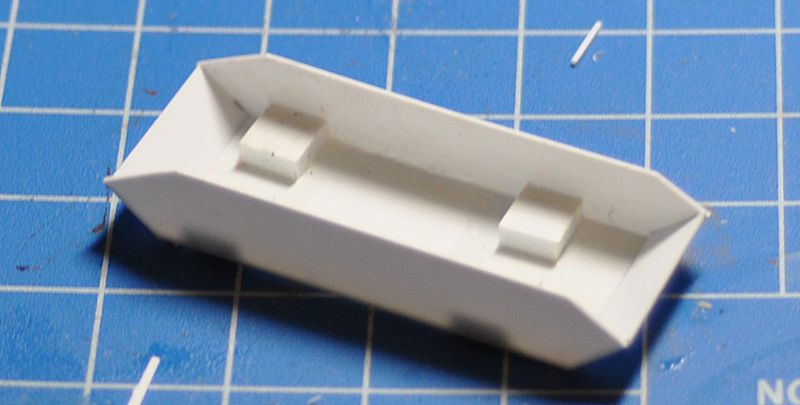

Companies like Battlefront, while still using metal for

their small scale figures, began to use a mix of polyurethane resins and white

metal for their vehicles. The casting technology

for resin is similar in many ways to metal, but resin is generally

cheaper. Plastic (both soft and hard)

had been used for decades in certain scales for miniatures, but the quality of

the plastic miniatures was almost universally inferior when compared to their

metal counterparts. One notable

exception would be plastic vehicles from companies like Citadel which

essentially used the same injection molding techniques and design used in scale

model kits.

As the new century dawned, Citadel began to move away

from metal all together and now use plastic not only for their vehicles, but

their 28mm miniatures as well. They have

a "finecast" range that is now, interestingly, resin rather than

metal. At the smaller scales like 15mm,

however, metal and resin still ruled. The

release of the Flames of War caused a surge in demand for 15mm miniatures and

vehicles which had to that point been a fairly fragmented market.

With the increase in popularity of the 15mm scale, it was

only a matter of time before new technology would be brought to bear into the

market. The primary drawback of

injection molded plastic is that it has a very high up-front cost. Creation of the molds for the kit sprues is

expensive, and to get good detail, complex (and even more expensive) sliding

molds are frequently required. However,

once the mold is created, a plastic miniature or vehicle is cheaper than its

metal and/or resin counterpart. Companies

like Zvezda and Plastic Soldier Company brought plastic to 15mm figures and

vehicles in a major way.

Recognizing the competitive threat, Battlefront had

already started to dip its toe into injection molded plastic with the tracks

for their Sherman and Sd Kfz 251 halftracks.

These were followed by the "Open Fire" boxed set featuring

decent plastic infantry, but the vehicles and anti-tank guns were a bit of a

mixed bag. Since then Battlefront has

continued to release plastic parts and kits.

Some have been excellent (the Panther tracks, T-34 kit, M113 kit, Sd Kfz

251 D) while others have had serious accuracy issues (Panzer IV J tracks, the

Panzer IV H kit).

The transition to plastic has not been without

controversy. Some people prefer the

weight of the older metal and resin miniatures.

Others prefer the detailing possible with plastic vehicles. Given the cost of setting up injection molds,

only high volume SKU's are good candidates for conversion to plastic, which

means that resin and metal are unlikely to completely go away in the near

future at 15mm scale. Resin and metal

are still going to be cheaper to set up, and can in certain circumstances still

offer detailing as good or better than plastic.

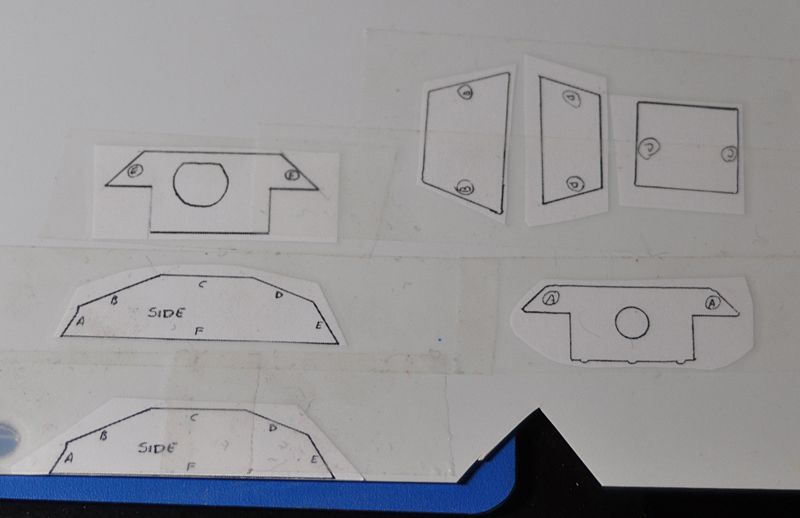

I personally like plastic for vehicles simply because it

makes assembly and conversion easier, and as any reader of this blog

understands I LOVE to do conversions. I

still have mixed feelings on the plastic figures at this point. Some seem to have excellent detail, while

others (like the tripod for the mortar in the open fire set) are crudely

simplified.

So what are your thoughts on plastic vs. metal/resin

miniatures? Post in the comments below!